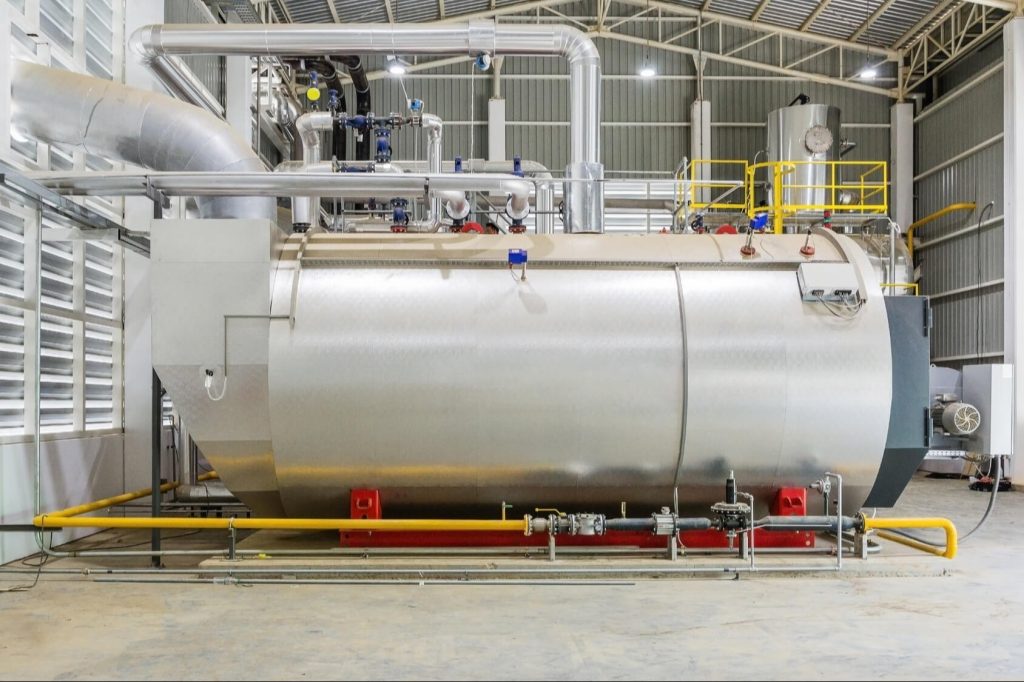

Industrial Steam Boiler Upgrades When and Why They Matter

Industrial steam boilers are essential assets in manufacturing, processing, and energy production. Over time, however, even the most reliable boilers experience wear, reduced efficiency, or outdated performance compared to modern standards. Upgrading is often a strategic decision that goes beyond routine maintenance. Knowing when and why to consider a boiler upgrade can help businesses maintain productivity, reduce costs, and support sustainability goals.

When to Consider Boiler Upgrades

Upgrading is not always about complete replacement—sometimes it involves integrating new components, controls, or systems. Key situations include:

- Age and Efficiency Decline

Boilers typically have a long service life, but older systems often consume more fuel and require frequent repairs. An upgrade can restore performance and reduce downtime.

- Rising Operating Costs

Increased fuel use, higher maintenance bills, or escalating repair expenses may signal the need for modernization.

- Regulatory Requirements

Updated emissions standards or safety codes may demand equipment changes that older boilers cannot meet without modification.

- Production Expansion

If industrial processes grow, an undersized boiler may struggle to meet demand. Upgrades can enhance capacity and ensure reliable output.

- Technology Advancements

Modern control systems, automation, and monitoring tools offer efficiency improvements that older systems cannot deliver.

Why Boiler Upgrades Matter

Choosing to invest in upgrades provides benefits that extend far beyond cost savings.

- Improved Energy Efficiency

Modernized boilers often use less fuel for the same output, helping reduce waste and optimize performance.

- Lower Environmental Impact

Reducing emissions and fuel use contributes to cleaner operations and compliance with evolving sustainability goals.

- Enhanced Safety

Upgrades often include advanced monitoring, pressure control, and fail-safe mechanisms that minimize risks.

- Reduced Downtime

Newer components and automation lower the risk of unexpected failures, allowing smoother production schedules.

- Better Return on Investment

While upgrades require upfront costs, the long-term savings in energy, maintenance, and compliance often outweigh initial expenses.

Strategic Considerations

Before deciding on a boiler upgrade, companies should evaluate:

- Current Performance Data – Fuel consumption, output levels, and maintenance history provide insight into whether upgrades are justified.

- Future Operational Needs – Anticipated growth or process changes should influence the scale of the upgrade.

- Cost-Benefit Analysis – Comparing upgrade costs with projected savings ensures decisions align with financial goals.

- Sustainability Targets – Upgrading can be part of a larger strategy to reduce carbon footprint and meet environmental commitments.

Conclusion

When it comes to industrial reliability and energy savings, industrial boilers excel, and you should definitely check it out for a deeper understanding. Industrial steam boiler upgrades are not just about keeping equipment running; they are about positioning operations for greater efficiency, reliability, and compliance. By recognizing the signs of declining performance and weighing the benefits of modernization, organizations can make informed decisions that protect productivity and support long-term success.